| Feed in size |

0-500 MM |

| Capacity |

50 – 220 TPH |

| Application |

Widely used in metallurgy, construction road, railway and commercial concrete industry sand and gravel aggregates. |

| Scope of Application |

It is suitable for crushing soft and medium hard ores for primary or fine crushing operations, such as granite, diabase, basalt, pebble, limestone, dolomite, metallic ores and non-metallic ores, etc. |

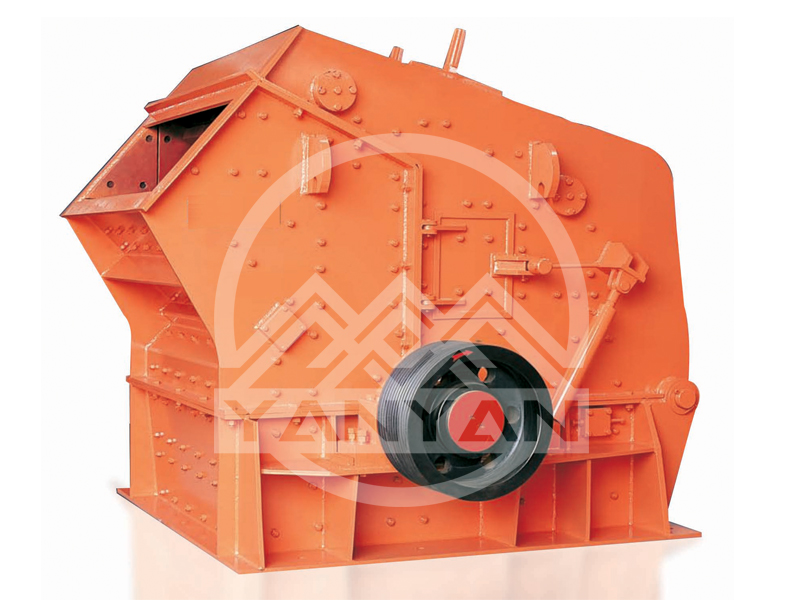

| Machine Introduction |

PF Impact Crusher uses impact energy to crush the materials. The rotor rotates at a high speed under the driving force of motor. The materials entering from the inlet impacts the plate hammer on the rotor and would be crushed under the high-speed impact of the plate hammer. The crushed materials would be thrown back to the liner plate for crushing again. Finally, the materials are discharged from the outlet of PF Impact Crusher. |

| Working Principle |

PF Impact Crusher breaks materials with impact force. When working, driven by a motor, the rotor rotates at a high speed. When materials enter the working area of hammer, they are crushed under the high-speed shock. Then broken materials are thrown onto the lining plate for another crushing. Finally, qualified materials are discharged from the opening. Adjusting the gap between the impact rack and rotor rack can change the granularity and shape of finished products. |

Performance

Integrated Application Of Latest Scientific Research Achievements

Based on the analysis of technical details and operating conditions of domestic and foreign impact crushers, Impact Crushers integrated many latest scientific research achievements, for example, those concerning crushing chamber, rotor and adjusting device. Thus, the crushing operation and maintenance reach higher level.

Higher Crushing Efficiency – Heavy-duty Rotor with Strong Rotary Inertia and High Precision

Impact Crusher adopts the heavy-duty rotor with strong rotary inertia and high precision. Meanwhile, it is equipped with high-quality bearings, ensuring the precision and big holding capability of the rotor. So, further, materials can be fully crushed. The crushing ratio is bigger.

Involute Crushing Chamber Ensuring Shape of Finished Products

The involute crushing chamber of Impact Crusher is efficient. Materials can be crushed several times inside the chamber. After crushing, finished products have good cubic shape which can better serve as high-quality aggregates.

Technical Parameters

| Model |

Rotor specification diameter*length MM |

Feed mouth size MM |

Max. Feed in size MM |

| PF-1007 |

Φ1000*700 |

400*730 |

≤ 300 |

| PF-1010 |

Φ1040*1000 |

400*1080 |

≤ 350 |

| PF-1210 |

Φ1250*1050 |

400*1080 |

≤ 350 |

| PF-1214 |

Φ1250*1400 |

400*1430 |

≤ 350 |

| PF-1315 |

Φ1320*1500 |

860*1520 |

≤ 500 |

| PF-1320 |

Φ1300*2000 |

993*2000 |

≤ 500 |

| PF-1515 |

Φ1550*1500 |

900*1650 |

≤ 500 |

| PF-1520 |

Φ1500*2000 |

980*2040 |

≤ 700 |

| Model |

Capacity TPH |

Power KW |

Overall size L*W*H MM |

| PF-1007 |

35-50 |

55 |

2400*1560*2600 |

| PF-1010 |

50-80 |

75 |

2400*2250*2650 |

| PF-1210 |

60-120 |

110 |

2700*2340*2900 |

| PF-1214 |

80-160 |

132 |

2700*2690*2890 |

| PF-1315 |

100-280 |

220 |

3100*3280*2670 |

| PF-1320 |

140-380 |

250 |

3220*3100*3120 |

| PF-1515 |

200-260 |

280 |

3400*3500*3280 |

| PF-1520 |

220-550 |

400 |

3960*3565*3300 |