Mobile plant introduction

YAN YAN MACHINERY wheel-type mobile plant is specially designed for capacity 50-300 tons/hour. It is suitable for various soft rock, hard rock, and construction waste crushing, screening and shaping operations.

Advantages of Mobile plant

1)Sufficiently Developed technical of the main equipment;

2)Fast assembly line meets operational requirements;

3)Modular and simple installation;

4)Flexible overall movement;

5)Standardization and generalization etc.

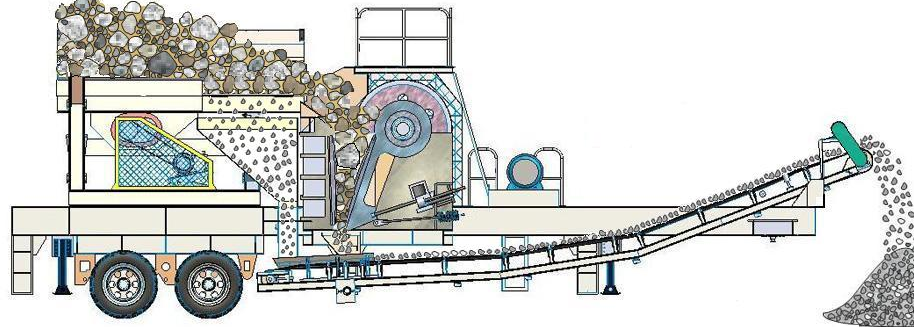

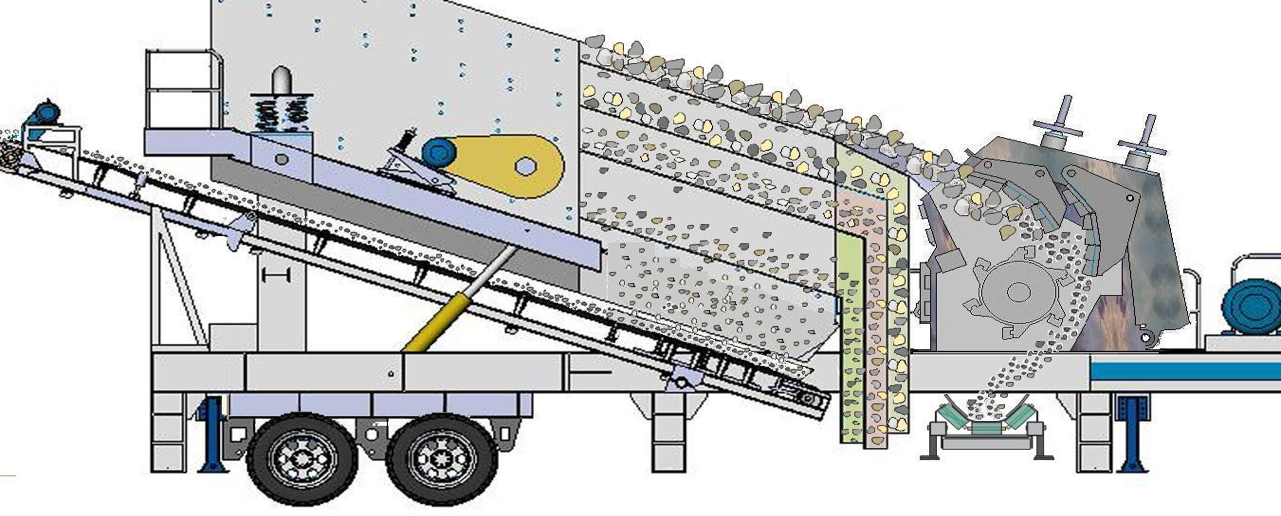

Working principle

The mobile plant usually uses an external electric power source. The raw materials are evenly sent from the vibrating feeder to the jaw crusher for coarse crushing. The coarsely crushed materials are sent to the cone crusher by the belt conveyor or impact crusher performs further crushing, and the finely crushed materials are transported to the vibrating screen for screening. The materials that meet the requirements of the finished product size is output by the finished product conveyor belt to be finished products. The materials that do not meet the requirements of the finished product size are returned to the cone/impact crusher is reprocessed to form a closed circuit for multiple cycles. The granularity of the finished product can be combined and classified according to the inquiry of customers.

Advantages of mobile crushing plant in engineering gravel

1. Freely transition, without resource constraints

The mobile crushing plant can move freely, it can be transported for long distances under the front of the car. It can deal with resource depletion or policy risks freely.

2. Quickly put into production and get immediate results

The mobile crushing plant is generally equipped with feeding equipment, crushing equipment and screening equipment, as well as belt conveying equipment. They are already assembled in the factory. After the mobile plant arrives on the construction site, only four outriggers need to be fixed. Embedded parts and anchor bolts can be completed during the production of the mobile plant in the factory. Compared with fixed crushing equipment, the mobile crushing station has a shorter commissioning period, and it can be put into production quickly and get returns immediately.

3. Save raw materials and transportation costs

The mobile crushing plant can be crushed nearby and processed on the spot, which can reduce the transportation cost of raw materials. Although the transportation cost per ton of raw materials is limited, it is a considerable number for a material yard with an annual processing capacity of one million tons. In addition, the mobile crushing plant enhances the user's ability to select resources. Users can choose low-cost raw materials. It is nothing more than driving the crushing plant, which is much lower than the transportation cost of the raw materials.

4. It can work alone, also be combined to work with other machine.

The mobile crushing plant is self-contained and can generally complete independent crushing tasks. For example, the mobile jaw crusher can complete the coarse crushing task, which can meet the needs of some construction sites. When encountering complex crushing tasks, mobile crushing stations can be combined flexibly to overcome them together. You can use one trailer alone, or you can combine them.

Mobile crushing plant series model and expression

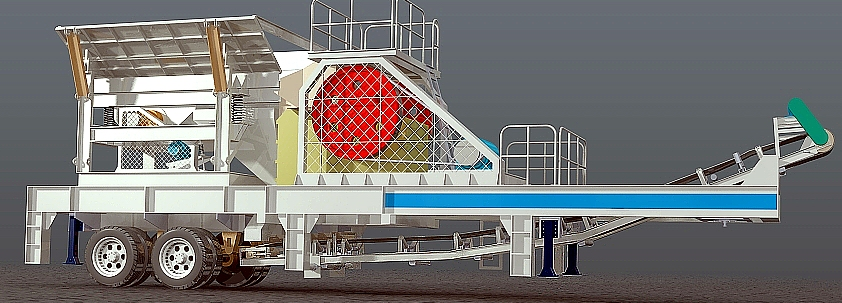

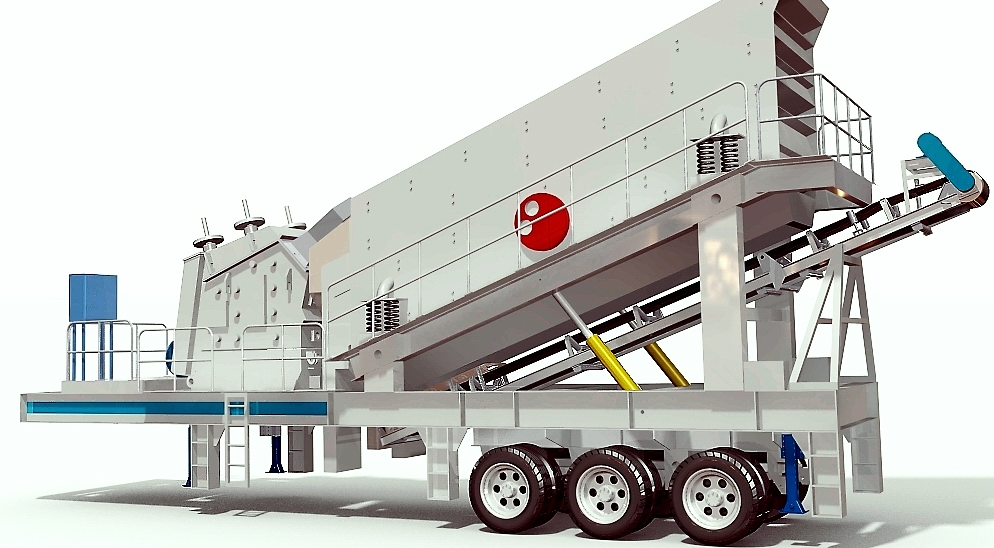

Jaw crusher series:

1.Features: large crushing ratio, strong crushing pioneer.

2.Product effect display diagram.

3.Model and main machine spec

| Spec |

Shipment Dimensions L *W*H (M) |

Vibrating feeder model |

| MT380E69 |

13.2*3.1*4.6 |

ZSW380*96 |

| MT420E750 |

15*3.3*5.5 |

ZSW420*110 |

| Jaw crusher model |

Belt conveyor model |

| PE-600*900 |

B650*7M |

| PE-750*1060 |

B800*9M |

| Power KW |

Generator |

| 91.5 |

opention |

| 134 |

opention |

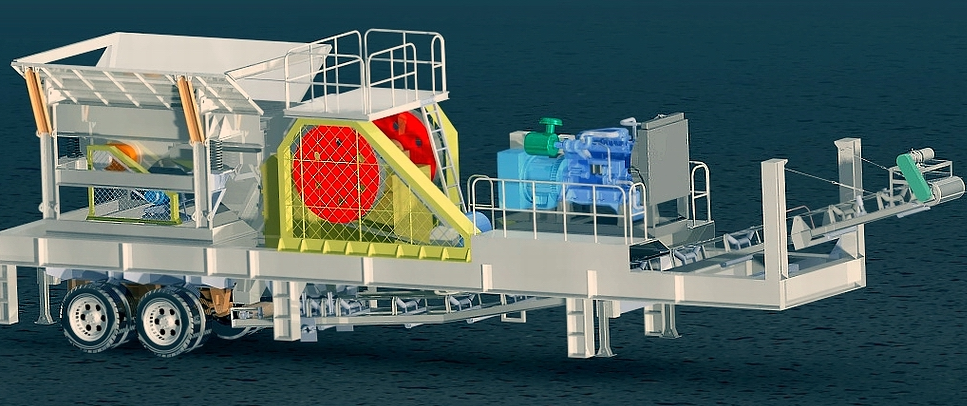

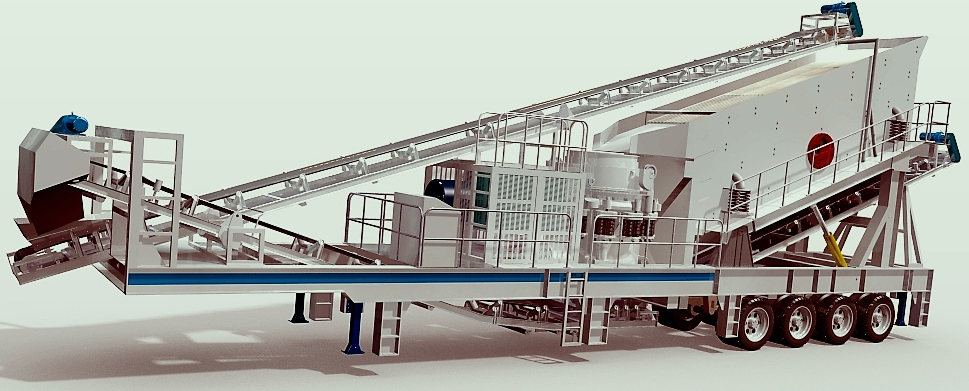

Impact crusher series:

4.Features: Processing capacity, efficient, economical, adaptable, crushing and screening treatment; Self-loading conveyor.

5.Product effect display diagram.

6.Model and main machine spec

| Spec |

Shipment Dimensions L *W*H (M) |

Vibrating feeder model |

| Y3S1860F1214 |

13.5*3*4.5 |

PF-1214 |

| Y3S2160F1315 |

14*3.2*4.8 |

PF-1315 |

| Jaw crusher model |

Belt conveyor model |

| 3YK1860 |

B650*8M |

| 3YK2160 |

B800*8M |

| Power KW |

Generator |

| 156 |

opention |

| 262.5 |

opention |

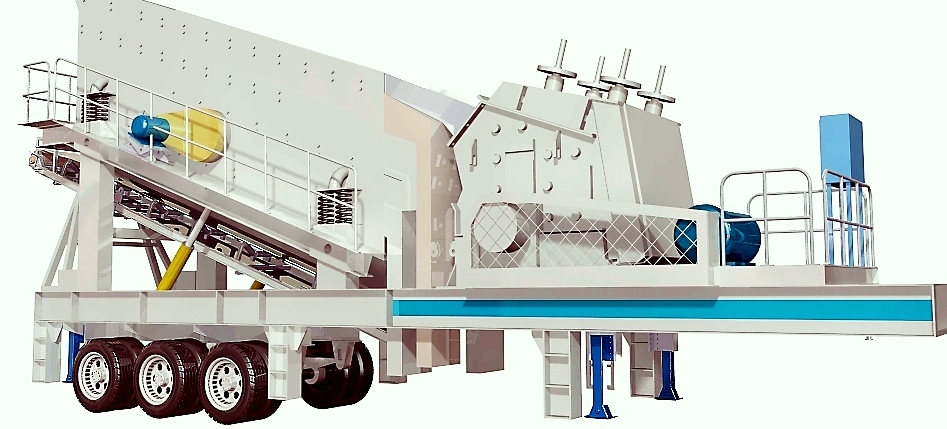

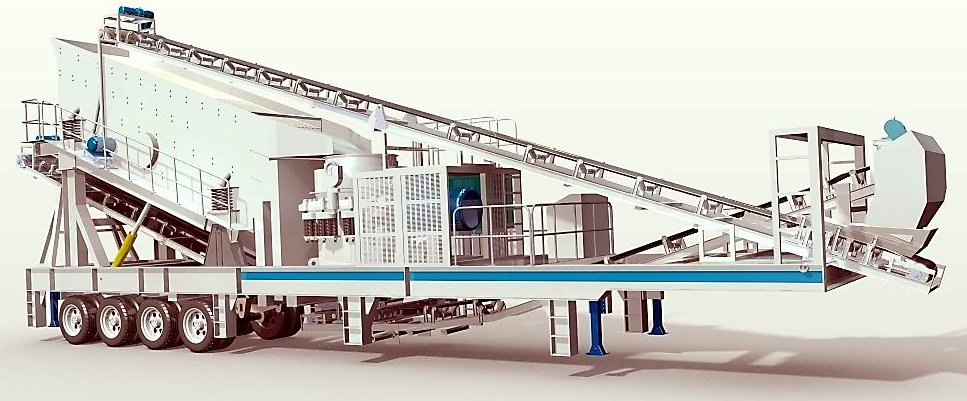

Cone crusher series:

7.Features: Processing capacity, efficient, economical, adaptable, crushing and screening treatment; Self-loading conveyor.

8.Product effect display diagram.

3.Model and main machine spec

| Spec |

Shipment Dimensions L *W*H (M) |

Vibrating feeder model |

| Y3S1860Y0917 |

14*3*4.5 |

MT0917 |

| Y3S2160Y1380 |

18*3.2*4.5 |

MT1380 |

| Jaw crusher model |

Belt conveyor model |

| 3YK1860 |

B650*8M |

| 3YK2160 |

B800*8M |

| Power KW |

Generator |

| 102.5 |

opention |

| 214.5 |

opention |

Description of the overall fixing method of mobile crushing plant (conventional)

After selecting the location of the mobile crushing plant operation site, do a good job of site leveling, after driving the mobile crushing plant to a suitable position, stretch out the lifting legs to erect the mobile crushing plant, dig a pit under the fixed legs, the size of the pit is determined according to the local soil quality, the looser the soil area and depth, and then fix the movable legs with connecting bolts on the fixed legs, pour the concrete foundation in the pit below the movable legs, and after the concrete solidifies, adjust the concrete surface to make the crushing plant support more stable, and finally retract the lifting legs. Auxiliary support tools such as sleepers can be appropriately added under the body to achieve sufficient stability.

Working plant case collocation

Indonesia project: crush limestone. One trailer is feeder + jaw crusher, and the second one is cone crusher + vibrating screen. The capacity is 120 tons/hour.

China customer: there are three sets of mobile trailers, which the capacity is 100 tons per hour sand making project. Including feeder + 600*900 jaw crusher, impact crusher + vibrating screen, sand making machine + vibrating screen.

Mexico Mobile Crushing plant: This project uses large-mouth impact crusher + vibrating feeder. Through the large-mouth impact crusher, the trailer has a certain degree of coarse crushing and fine crushing capabilities at the same time.

Cameroon plant : The mobile trailer shipped to Cameroon has a capacity of 40-60 tons/hour, including vibrating feeder + jaw crusher + impact crusher + vibrating screen. When the capacity is not large, one trailer can meet the demand.