The natural gypsum powder includes anhydrous gypsum and CaS04.2H2O, if you want to commercialize the gypsum powder, you should adopt the CaS04.2H2O, after removing part of water by heating, it will become CaS04.1/2 H20. CaS04.1/2 H20 is the final product which you can use it to produce gypsum board other gypsum product. After calcining, CaSO4.1/2H2O is widely used in paper faced gypsum board and gypsum block and painting gypsum powder and model. Natural gypsum generally includes dehydrate gypsum and anhydrous gypsum. In order to get the valuable materials, generally, we get semi-hydrated gypsum through heating the dehydrate gypsum.

Applications

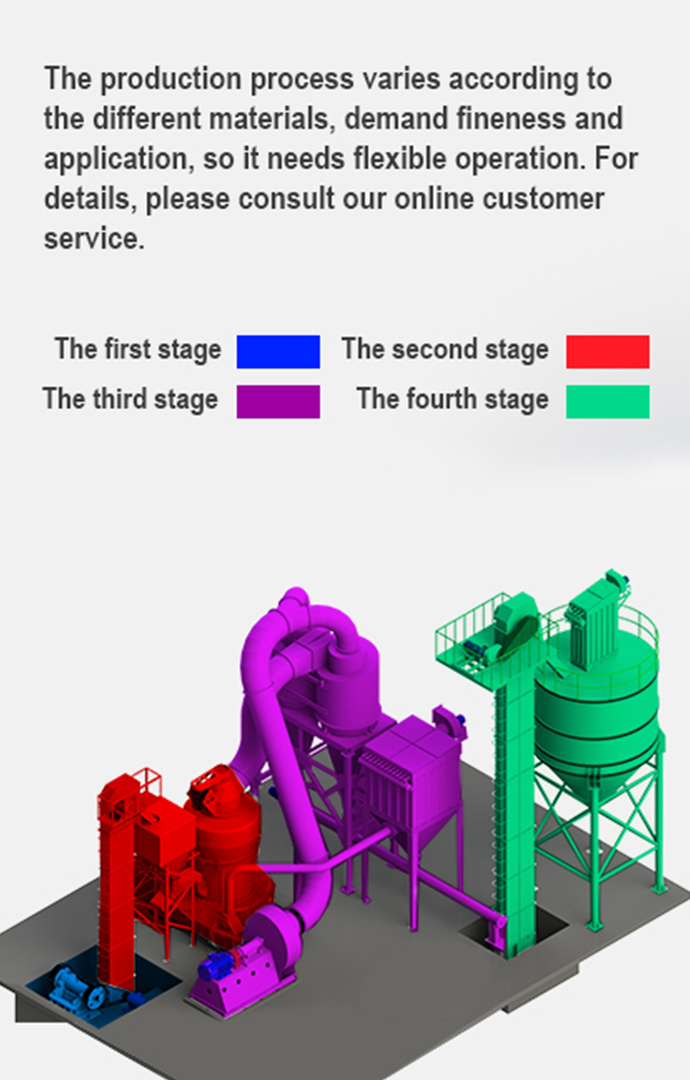

This project can be dividing into six systems:Crushing , Grinding, Calcination, aging in silo , dust collection, and heating supply.

Brief introduction of technology:

1. Crushing the gypsum rock into maximum 5mm size

2. Lifting the 5mm size gypsum particle into silo for storing, when the silo is full, the crusher will stop working automaticly, which can save energy.

3. Milling the gypsum rock particle into 80-120mesh powder by our Grinding mill. The powder is classified through a separator inside grinding mill. The qualified powder in required fineness shall be carried to the calciner, while the unqualified powder shall be returned to the grinding mill for further process.

4. Calcining the CaS04.2H2O into CaS04.1/2H2O by vertical boiling furnace.

5. Lift the finished gypsum powder into finished powder silo.

6. Packing the gypsum powder into 15-50kg bag for selling or transport the gypsum powder directly to gypsum board machine for 24 hours.