| Feed in size |

0-930 MM |

| Capacity |

20 – 650 TPH |

| Application |

Widely used in metallurgy, construction road, railway and commercial concrete industry sand and gravel aggregates. |

| Scope of Application |

It is suitable for crushing soft and medium hard ores for primary or fine crushing operations, such as granite, diabase, basalt, pebble, limestone, dolomite, metallic ores and non-metallic ores, etc. |

| Machine Introduction |

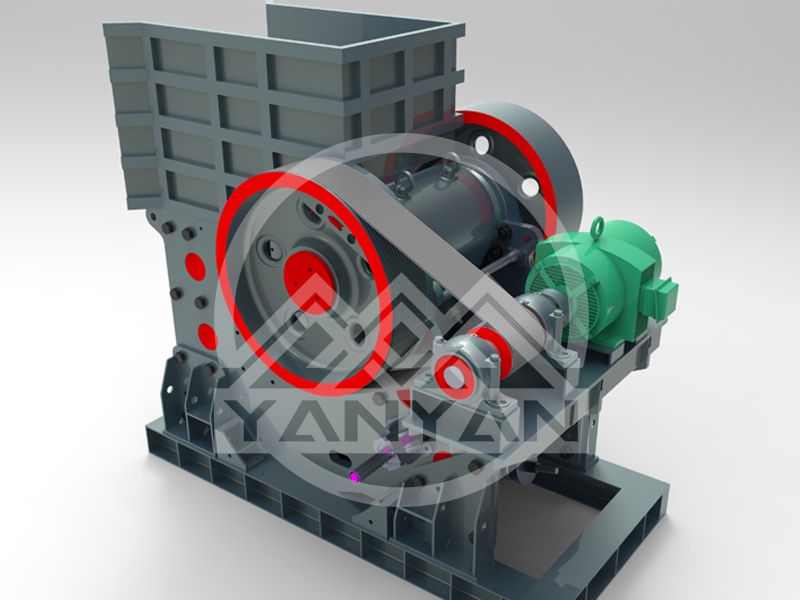

PEW Jaw Crusher is a hydraulic crushing machine. This jaw crusher is a perfect combination of modern science and technology and the production practice, which can better satisfy the automatic production demands of vast customers. |

| Working Principle |

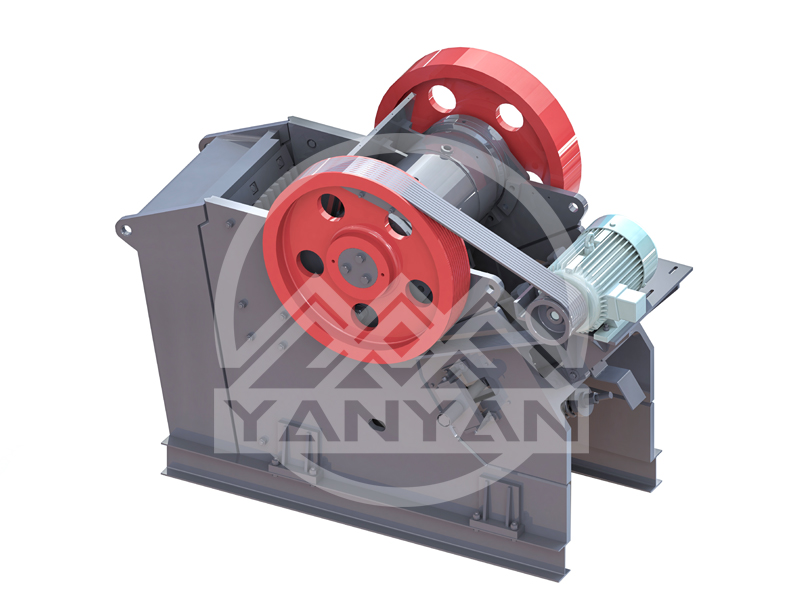

Firstly, the motor drives belt and pulley to make the movable jaw move back and forth, up and down around the eccentric shaft. When the movable jaw pushes the movable jaw plate towards the fixed jaw plate, materials get crushed. When movable jaw and plate move backwards under the action of the eccentric shaft and spring, the materials crushed before would be discharged from the port under the jaw plate. As the motor works continuously, the movable jaw can crush or discharge materials periodically, so that volume production can be achieved. |

Performance

Stable Structure, Reliable Performance

YAN YAN MACHINERY uses high-quality steel castings for core load bearing parts of jaw crusher, i.e. moving jaw and bearing block. This technology not only guarantees the perfect fitting and seamless connection of crusher rack, but also enhances the radial strengths of the parts, thus realizing more reliable performance and higher durability of the jaw crusher.

Hydraulic Control, Convenient Cavity Clearing

PEW Jaw Crusher is equipped with the hydraulic oil station to ensure that the lubrication system supplies oil to the lubrication components, providing security for the safe operation of the machine. At the same time, if the crusher shuts down with load, the hydraulic clearing system can quickly clean the crushing chamber, greatly reducing downtime.

V-type Crushing Chamber, Toothed Guard Board

PEW Jaw Crusher has more reasonable "V" crushing chamber and toothed guard board. By them, the actual size of feeding materials can be consistent with ideal size, which can effectively enlarge the crushing space. Besides, materials wouldn’t pile in the crushing chamber, so the crushing ratio and capacity can reach the optimal status and the utilization of jaw plates could extend.

Wedge Device, Convenient Adjustments

PEW Jaw Crusher adopts a wedge discharging adjustment device, so that the machine can turn the discharge port to a preset value within minutes even under the idling circumstance. In cooperation with the hydraulic system, automation is available. Compared with the old gasket discharging adjustment device, this device is simpler, safer and quicker.

PEW Jaw Crusher Factory trial

Technical Parameters

| Model |

Mouth size MM |

Max. Feed in size MM |

Output size MM |

| C80 |

520*800 |

≤ 420 |

60-150 |

| C100 |

760*1000 |

≤ 630 |

70-175 |

| C110 |

850*1100 |

≤ 720 |

80-200 |

| C120 |

900*1200 |

≤ 750 |

90-280 |

| C145 |

1100*1450 |

≤ 920 |

125-275 |

| C160 |

1200*1600 |

≤ 1020 |

150-300 |

| C200 |

1500*2000 |

≤ 1200 |

170-300 |

| Model |

Capacity TPH |

Power KW |

Overall size L*W*H MM |

| C80 |

80-290 |

75 |

2650*1540*1780 |

| C100 |

130-420 |

110 |

3700*2440*2520 |

| C110 |

160-550 |

160 |

3800*2450*2550 |

| C120 |

200-680 |

160 |

4450*2310*3410 |

| C145 |

320-950 |

200 |

4400*3060*3210 |

| C160 |

410-1150 |

250 |

5700*3650*3550 |

| C200 |

610-1510 |

400 |

6500*3990*4260 |